AAR Intermodal Loading Guide Excerpt for Cargo Containment Load Flooring

The following information is excerpted from the INTERMODAL LOADING GUIDE for Paper Products, Circular No. 43-D, August 2001, Published & Distributed by the AAR. It’s purpose is to depict correct loading methods for rail with pulpboard products, with certified bulkhead and securement products. Those method descriptions for which Load Lock is approved are listed briefly below. For complete load instructions and information, contact the American Association of Railroads at www.aar.org .

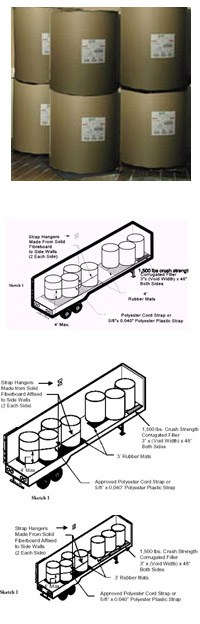

Method E-4

58″ Diameter Roll Pulpboard on End Using Rubber Mats

This method is for 58″ diameter roll pulpboard loaded on end in a 1-1 offset pattern in a trailer or container for intermodal service. Plan the load to equalize the weight on each side of the trailer or container. Since roll weights vary, this will require attention to pre-planning. A balanced load is required for the stability and success of this loading method.

The following rubber mats have been evaluated by the AAR and found acceptable for the E-4 loading method:

Load Lock [3 mm (0.125″) thick].

In 4′ x 14′, 16′ or 17′ lengths.

Method E-18

Split Loads of 58″ Diameter Roll Pulpboard on End Using 3′ Wide Rubber Mats

(If loading split loads of 58″ diameter roll pulpboard on end in trailers having large metal plates approximately 9 in length at the nose use Method E-19)

This method is for split loads of 58″ diameter roll pulpboard loaded on end in a 1-1 offset pattern in a trailer or container for intermodal service. A maximum of 8 rolls may be loaded in a trailer or container using this method. The loads generally consist of 7 or 8 rolls loaded in two sections in the trailer or container. Plan the load to equalize the weight on each side of the trailer or container. Since roll weights vary, this will require attention to preplanning. A balanced load is required for the stability and success of this loading method.

The following rubber mats have been evaluated by the AAR and found acceptable for the E-18 loading method:

Load Lock [3 mm (0.125″) thick]

Method E-19

Split Loads of 58″ Diameter Roll Pulpboard on End Using 3?Wide Rubber mats When Stowed in Trailers Having Large metal Plates Approximately 9? in Length at the Nose

This method is for split loads of 58″ diameter roll pulpboard loaded on end in a 1-1 offset pattern for intermodal service in a trailer or container having wood floors with large metal plates approximately 9′ in length at the nose. A maximum of 8 rolls may be loaded in a trailer or container using this method. The loads generally consist of 7 or 8 rolls loaded in two sections in the trailer or container. Plan the load to equalize the weight on each side of the trailer or container. Since roll weights vary, this will require attention to pre-planning. A balanced load is required for the stability and success of this loading method.

The following rubber mats have been evaluated by the AAR and found acceptable for the E-19 loading method:

Load Lock [3 mm (0.125″) thick].

We would like to hear from you

please, ask us a question or request a quotation.

Benefits and Advantages of Quotation requests

Great Manufacturer Pricing

Customized Quote on Different Quantities (Quantity Discounts)

Customized Shipping Methods

No Hidden Charges

Promotes Better Customer Communication

Provides Product Details and Installation Instructions

Respectfully Yours,

NGT-Recycled Rubber

Request a Quote Below